FAQ baseTherm®

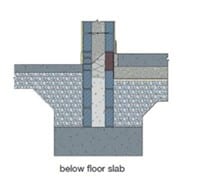

- Below a concrete floor slab.

- Below a floor screed on a concrete slab with a hardcore base.

- Above a suspended concrete floor (e.g., block and beam) with a floor screed.

-

baseTherm® Low Lambda

-

baseTherm® 150

-

baseTherm® 200

-

baseTherm® 250

- Meets I.S. EN 16025‑1 and I.S. EN 16025‑2 (standards relating to bound EPS ballasting / BEPS) for thermal and/or sound insulating products. (source:basetherm.com)

- Certified by NSAI Agrément (Certificate No. 22/0430) for compliance with Building Regulations. (source: NSAI)

- EPD certified; includes life‑cycle environmental impact assessments. (Source: Irish Green Building Council)

BIM objects

- Location: The BIM digital objects for the baseTherm® Floor Insulation System are available on NBS Source, an online library for BIM objects.

- Purpose: These objects allow designers and architects to integrate the product directly into their Building Information Modeling software, streamlining the design and specification process.

-

- It was Ireland’s first NSAI-accredited liquid floor insulation

- It serves both domestic and commercial construction applications

- It is produced and installed on-site using a Mobile Floor Insulation Factory

- Tel: Sales +353 (0) 87 333 0683 or +353 (0) 87 223 2456

- Email: sales@basetherm.com

- It operates under an SCS-registered ISO 9001:2015 Quality Management System

- baseTherm® is a wholly Irish-owned company that uses a local team to service its customers

- baseTherm® never uses third parties

Contact baseTherm® today

LEARN MOREHere’s why baseTherm® works so well with UFH:

- Encapsulates services and pipes: As a liquid insulation, baseTherm® fully encapsulates any pipework or services on the subfloor. This eliminates voids and cold bridges that can cause uneven temperatures and heat loss.

- Creates a level base: The poured insulation creates a seamless and perfectly flat substrate for the UFH pipes and the final screed. This ensures a uniform thickness of screed for a more effective and consistent heat output.

- Installation process: After the baseTherm® is fully dry, depending on site conditions, a 500-1000 gauge (125-250 micron) separation membrane (polyethene) is installed, prior to installation of underfloor heating pipes. Edge insulation of 8mm minimum should also be formed around the perimeter (walls, columns, etc.). After completion, a self-smoothing screed to BS 8204-7 or sand & cement screed to BS 8204-1 can be installed.

NOTE: UNDER FLOOR HEATING SYSTEMS (UFH) The heating pipes or cables should be fully secured to the surface of the baseTherm® to prevent flotation during screed installation. The manufacturer of the heating system should provide their installation details, but it is essential to ensure that the heating elements cannot float.

Please refer to baseTherm® Brochure for further detailed information.

For example, per day:

- A 400m² area at 150mm depth, or

- A 300m² area at 200mm depth.

Before installation, our professional team will assess your project size and provide a clear, tailored timeline to ensure smooth delivery.

On average, this takes between 4 days and 1 week, depending on site conditions such as temperature, ventilation, and humidity. Proper drying ensures the product reaches its full insulation performance.

To ensure great results, we strongly recommend testing a small area after 4 days to confirm it is ready for re-entry, as longer waiting times may be required depending on the aforementioned site conditions.

Yes, baseTherm® Poured Floor Insulation can be used with all types of floor screeds manufactured to comply with BS 8204 and EN 13813 standards.

It is suitable for use with:

- Cement-based screeds, including traditional sand and cement floor screeds and cement-based flowing screeds.

- Calcium sulphate screeds, such as Alpha Hemihydrate and Anhydrite floor screeds.

- Polished floor screeds.

This ensures efficient heat transfer, making it an ideal choice for underfloor heating (UFH) systems in both new builds and retrofit projects across Ireland.

The declared thermal resistance (R-value) is calculated to IS EN ISO 6946 and IS EN ISO 13370. The value of the declared installed thermal resistance shall be rounded down to the nearest 0,05m2K/W.

Adhering to current guidelines for the Republic of Ireland, we can achieve U Values of 0.15W/m2K or better, meeting and exceeding current building regulations standards for energy efficiency. This ensures superior thermal performance, reduced heat loss, and improved comfort within your home or building.

Yes, baseTherm® Liquid Floor Insulation is ideal for retrofitting and refurbishing older homes. It can be used across all types of home projects, including older properties that need new or upgraded floor insulation. The product flows easily, encapsulating pipes and creating an even layer that maintains heat efficiently—a highly effective way to make your home warmer and reduce energy loss.

Absolutely. Using baseTherm® as a liquid floor insulation in existing or older homes is one of the most effective ways to reduce heat loss and improve energy efficiency. It enhances thermal performance, helps lower heating costs, and brings your home closer to modern building regulation standards – all while providing a more comfortable living environment.

baseTherm® Liquid Insulation for Floors can be poured at depths ranging from 50mm to 1000mm. The depth chosen will depend on your project’s structural and insulation requirements. Please note that greater depths may increase drying times. We’ll always advise on the best application to achieve long-lasting, efficient results. (Contact baseTherm® to discuss your specific requirements.)

Yes. It contributes to Near Zero Energy Building (NZEB) compliance by improving airtightness and reducing thermal bridging – a key factor in achieving BER A-rated homes in Ireland.

Yes, baseTherm® Pumped BEPS Floor Insulation can be applied on suspended timber floors, provided the structure is properly prepared and reinforced. It offers a modern way to enhance insulation and reduce heat loss in older or traditional Irish homes with suspended flooring systems. Professional assessment is always recommended to ensure compatibility and load-bearing suitability before installation. (Contact baseTherm® to discuss your specific requirements).

baseTherm® 200 and 250 are rated A1 to EN 13501-1. An A1 fire rating is the highest level of fire resistance for construction materials under the European EN 13501-1 standard, classifying a material as completely non-combustible, meaning it does not contribute to fire growth or spread, and produces no significant smoke or flaming droplets, even under extreme heat.

baseTherm® Low Lambda and 150 are rated A2 to EN 13501-1. While not as completely non-combustible as A1-rated materials, A2-rated products will not ignite easily, produce minimal smoke, and typically produce no flaming droplets. This makes them suitable for high-risk construction of tall buildings where fire safety is paramount. (source: baseTherm® Brochure).

PIR boards typically achieve B or C rating; EPS boards typically achieve E rating to EN 13501-1.

When installed correctly, it lasts the lifetime of the building. It won’t degrade, settle, or lose its insulation value, giving decades of reliable performance.

Some of the key benefits of baseTherm® are:

- Seamless, void‑free poured installation, reducing gaps / thermal bridging / cold spots.

- On‑site production via a highly efficient, computer-programmed Mobile Insulation Factory.

- Minimal waste by not having to cut awkward, rigid boards.

- Conforms to even out uneven surfaces, fills voids, and reduces thermal bridging more effectively than rigid boards, which often require very precise cutting and fitting.

- Rapid pumped installation at 60m3 per day, minimum effort – reduces delays for follow-on trades.

- Lightweight, enhancing ease of installation and reducing loading on the floor structure.

- Acoustic benefits due to its composition.

- baseTherm® 200 and 250 are rated A1 to EN 13501-1. baseTherm® Low Lambda and 150 are rated A2 to EN 13501-1. (Source: baseTherm® Brochure) PIR boards typically achieve B or C rating; EPS boards typically achieve E rating to EN 13501-1.

- Published baseTherm® specific EPD (via EPD Ireland) covering the variants: baseTherm® Low Lambda, 150, 200, and 250. EPDs have a major role to play in enabling better product choices in delivering lower-carbon buildings

- Crystal-clear competitive pricing – without surprises as rates are for supply & install – with a VAT rate of 13.5% (in ROI).

- Produced and installed by a local team of highly efficient professionals – no third parties.

Yes, if adjustments are required after your baseTherm® liquid insulation for floors has been installed, it can be cut or trimmed on-site when dry. This flexibility allows for any last-minute changes to pipework, fittings, or floor layouts, ensuring a smooth installation process without compromising insulation performance.

Considerations include:

- Depth and finished floor height: Since baseTherm® Pumped BEPS Floor Insulation is installed by pumping and then covered with a screed (or slab, etc.) the full build-up height must be considered. Depending on the grade, it may require deeper insulation than rigid boards to achieve a given U‑value. Contact baseTherm® to discuss your specific requirements.

- Structural loading: baseTherm® is non‑structural, so any loads must be supported by the structural slab. baseTherm® may be installed below the structural slab. See further detailed information: baseTherm® Brochure.

- Drying time/curing: As with any screed/mortar, there are specific curing times before finishing flooring can be laid. baseTherm® guidance should be followed. See further detailed information: baseTherm® Brochure. To achieve the best results, you must allow baseTherm® Poured BEPS Floor Insulation to fully dry/cure before re-entry or allowing foot traffic of any description. On average, this takes between 4 days and 1 week, depending on site conditions such as temperature, ventilation, and humidity. To ensure great results, we strongly recommend testing a small area after 4 days to confirm it is ready for re-entry as longer waiting times may be required depending on the aforementioned site conditions. Proper drying ensures the product reaches its full insulation performance. Contact baseTherm® to discuss your specific requirements.

- Access and logistics: Because installation requires a baseTherm® Mobile Insulation Factory and pump equipment, site access must be able to accommodate.

With crystal-clear competitive pricing, please contact baseTherm® to discuss your specific requirements.. Rest assured, your quote will be without surprises, as rates are for supply & install – with a VAT rate of 13.5% (in ROI).

Contact baseTherm® today

LEARN MOREYes, baseTherm® offers a comprehensive CPD focusing on the wealth of benefits of seamless, void-free, poured floor insulation.

This is conducted through our partners at Smet Building Products Ltd (SMET). Please use the Contact Us Form – here to organise a bespoke session that best fits your schedule and goals.

Contact SMET to arrange a CPD for your office

WANT TO LEARN MOREArchitects and Designers, you can rest assured that baseTherm® is also listed on NBS Source, with both BIM objects and specification data available.

No, not in new builds. However, as renovation and refurbishment jobs generally do not provide a reasonably dry substrate that is free of grease and other impurities, we recommend installing a suitable separating membrane before your baseTherm® pour.

Yes, electric underfloor heating can be used in combination with baseTherm and floor screed. Electric underfloor heating is often best installed directly above the cured screed (or within a thin levelling compound) and beneath the final floor covering. This method offers faster warm-up times and is ideal for retrofitting.

There are four main grades. These differ depending on thermal performance requirements and load/usage.

- baseTherm® Low Lambda

- baseTherm® 150

- baseTherm® 200

- baseTherm® 250

The four grades differ in the following characteristics: Density, Compressive Strength, and Thermal Conductivity. The denser the grade, the higher the compressive strength, the higher the thermal conductivity. Please refer to baseTherm® Technical Characteristics Brochure for further detailed information.

The minimum thickness required depends on the total square meters and total exposed perimeter length of your ground floor. These two measurements determine the thickness needed to achieve a u-value of 0.15 (when underfloor heating is present) or 0.18 when no underfloor heating is present. baseTherm® Liquid Insulation for floors can be poured at depths ranging from 50mm to 1000mm. Please refer to our U-value tables for a quick reference of the thickness required for your specific project. baseTherm® Technical Characteristics Brochure.

Liquid or self-smoothing screeds can be installed at a minimum depth or thickness of 35mm for domestic buildings. For commercial buildings, a minimum of 40mm screed depth or thickness is required.